BLUE POWER

Innovative solutions for

Casting processes and powder production

from a single source ...

We offer a wide range of systems for casting processes

with lost and continuous moulds, for the production of

first-class semi-finished products, for recycling and for

the production of high-quality metal powders:

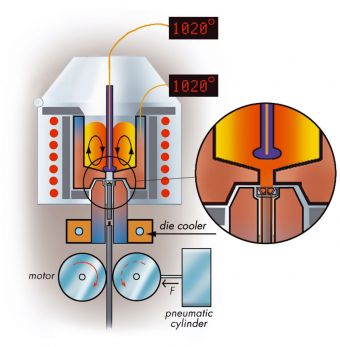

• Compact vacuum-pressure casting systems MC series foruse

in R&E as well as for casting the smallest

parts. Temp. max up to 2,000° C.

• Vacuum pressure casting systemsVC series

(plugrod principle)

with crucible volume of up to 25 l.

Up to 1,700°C.

• Vacuum-pressure casting systems

VT C-Series (tilt casting systems) forhighly melting

alloys such as steel, platinum or titanium.

• Continuous casting plants (CC/VCCseries) for the production of

high-quality strips, wires, pipes.

Also with vacuum function as well as with cutting,

sawing or rewinding devices.

• Granulation plants andmicro-granulation plants

• Melting plants

and tipping furnaces

up to 12 l crucible volume

All Blue Power systems are equipped with self-developed

induction generators, with program control and with extensive

interfaces according to Industry 4.0 standard.

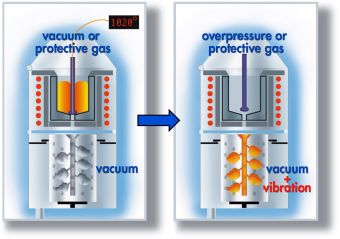

Numerous Blue Power-owned technologies ensure the best

possible results,such as the Blue Power vibration system.

B or sophisticated vacuum overpressurecontrolsfor optimized

mold filling and oxidation avoidance.

The fine casting has gotten competition. We support

you on the way to the future.

New manufacturing technologies should never be underestimated.

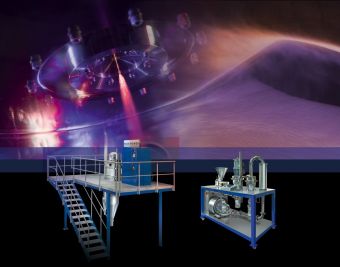

That's why we started developing powder digestion systems

and winds in the early days of additives manufacturing.

In this way, we can provide comprehensive advice to our

customers from the foundry industry who want to expand their

range and support them with innovative technology.

Since we know that powder quality is of fundamental importance

in all additive processes, we do not focus on individual additive

processes, but offer you the equipment with which you

can quickly and safely produce the optimal powder

specification:

Our AU series atomizers are optimized for smaller

batches and frequent changes of alloyor particle size without

cross-contamination and are characterized by short cycle

times.

You can choose between production capacities of

1.5 l, 3.4 l, 12 l and 25 l.

Depending on the version andcrucible used, the AU systems are

suitable for alloys based on of Cu,Au, Ag, Sn, Fe,Co,

Ni, Pd, Pt and others such as e.B. Al (on request).

The melting takes place underprotective

gas/vacuum. High-precision temperature/process inflation

(also remotely controlled) ensures

reproducible and consistently high powder quality.

Our wind screeners (AC series )are designed for the economic

separation of metal powders into fine and coarse parts, whereby

the separation limitcan be defined almost at will.